The UHMWPE Conveyor Roller is an excellent alternative to traditional metal rollers and is designed for the most demanding applications.

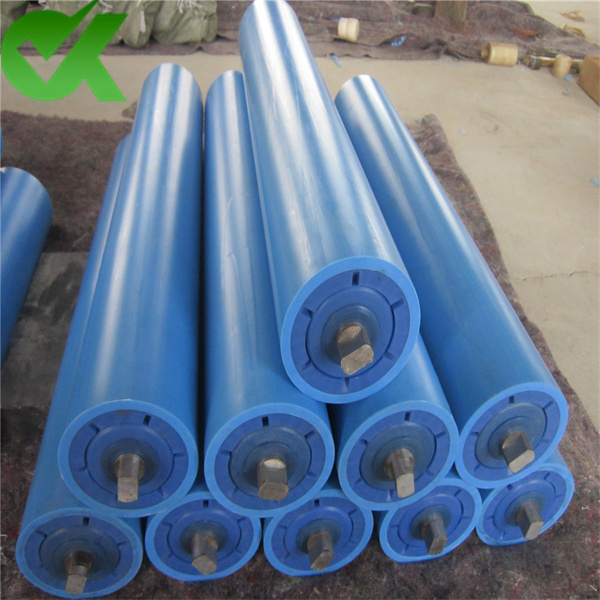

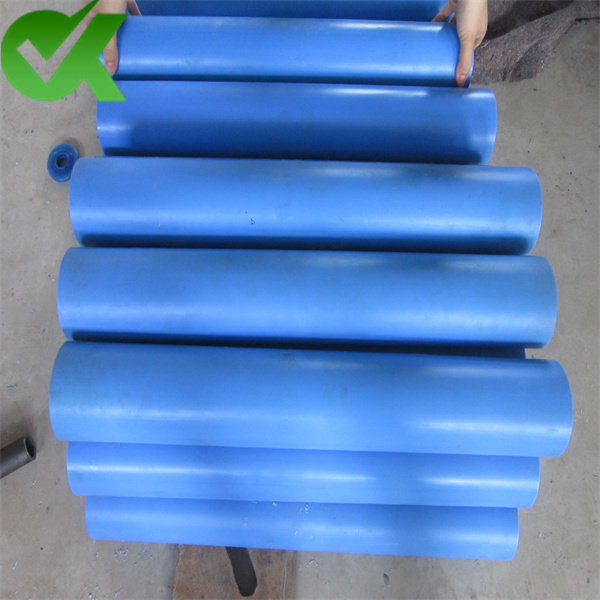

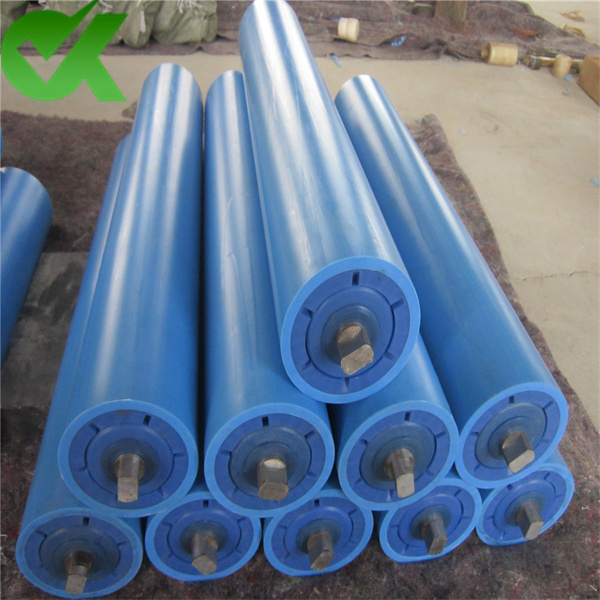

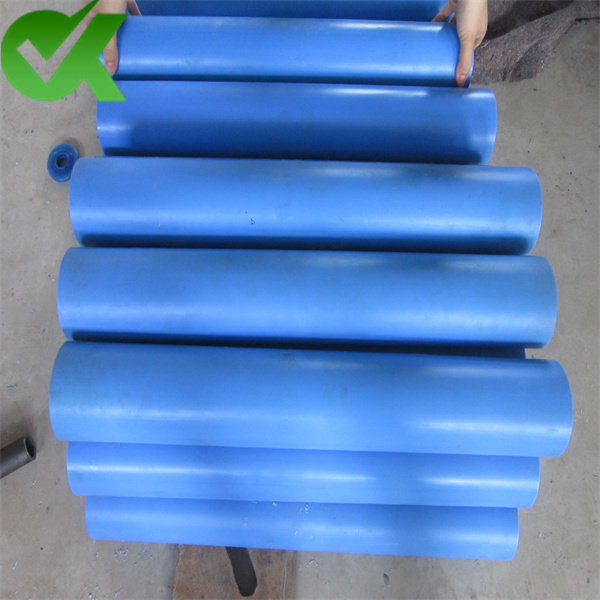

The outer layer of the UHMWPE Conveyor Roller of Henan OKAY is made of high-density polyethylene. The shaft is made of structural carbon steel. The double-sided bearing seat is protected by polyethylene, and the structural design of the product can effectively prevent moisture and dust on the bearing. The UHMWPE Conveyor Roller is an excellent alternative to traditional metal rollers and is designed for the most demanding applications. The drum is made of HDPE (High Density Polyethylene). Our UHMWPE Conveyor Roller is suitable for harsh working conditions such as high dust, humidity, low temperature and salt water environments. Extremely low noise levels and low rotational resistance are also features of the UHMWPE Conveyor Roller. All of this can significantly increase service intervals for servicing conveyors while significantly reducing the cost of transporting bulk materials, ultimately increasing the efficiency of conveyor equipment.

Advantages of UHMWPE Conveyor Roller:

Longer service life.

The surface is self-lubricating and not easy to adhere.

Resistant to corrosion and chemical liquids.

Can withstand higher heavy loads.

Highly dust and moisture resistant.

Lighter weight, lower energy consumption.