High molecular weight polyethylene sheet has excellent resistance to most domestic and industrial chemicals.

High molecular weight polyethylene sheet has excellent resistance to most domestic and industrial chemicals. Certain types of chemicals can cause chemical corrosion. The polymer is non-hygroscopic and has good water vapor resistance, and can be used for packaging purposes. HDPE sheet has good electrical properties, especially the high dielectric strength of the insulation, making it very suitable for wires and cables. Medium to high molecular weight grades have excellent impact resistance, even at room temperature and even at low temperatures. The unique characteristics of various grades of HDPE are the proper combination of four basic variables: density, molecular weight, molecular weight distribution and additives. Different catalysts are used to produce customized polymers with special performance. These variables are combined to produce HDPE grades for different purposes; achieving the best balance of performance. It has good chemical stability, can resist most acids, alkalis, organic solutions and hot water, and has good electrical insulation.

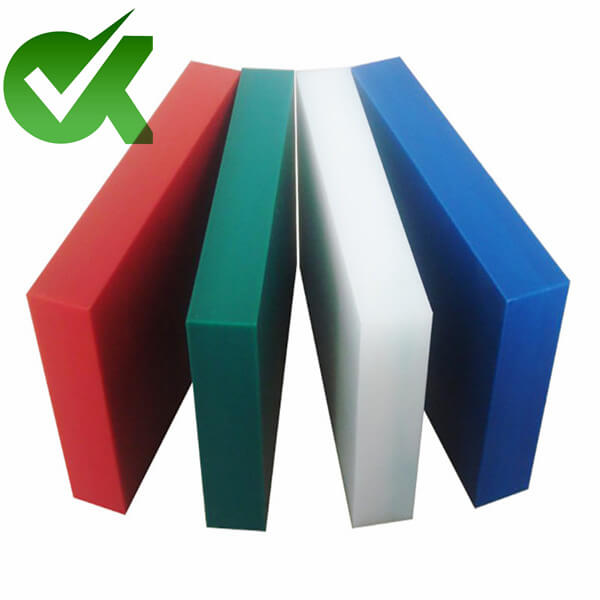

The characteristics of high molecular weight polyethylene sheet: impact resistance (impact resistance ranks first among plastics), good corrosion resistance, excellent chemical resistance, lower density than other thermoplastics, low friction coefficient, superior mold release performance, extreme The bottom water absorption, excellent electrical insulation and static resistance, moderate mechanical strength, rigid creep resistance, excellent machining performance, continuous nature, and good resistance to high-energy radiation. The main advantages of HDPE board are toughness, wear resistance and stress cracking resistance. HDPE sheet also has lubricity, chemical resistance and excellent electrical properties of general HDPE. Its development success is generally regarded as one of the top ten scientific and technological achievements in the 20th century.